Laser Cutting Services

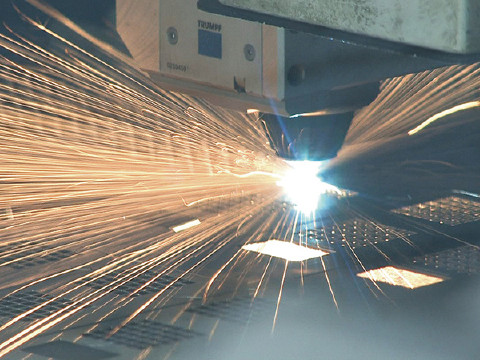

Cirrus Laser now only use solid state lasers. A 6kW disk on Laser #12 and 4kW on Laser#13, both with a wavelength of 1.03 microns, cutting on 3.0 x 1.5m beds.

Laser #11 - This is a 5 axis laser machine that shares the 6kW disk laser, used both for cutting and welding. Solid state lasers are good at cutting steel and stainless steel but also reflective materials such as brass and copper.

Laser #10 - A dedicated laser marking machine which uses a 12w solid state laser for marking all types of materials including plastics. Typically we use annealing for stainless steel (leaving smooth surfaces) anodised aluminium we use white engraving and deep engraving on most other metals. Deep engraving removes material, therefore not as smooth as annealing.

More details of our machinery can be found on the Laser Cutting Machines page.

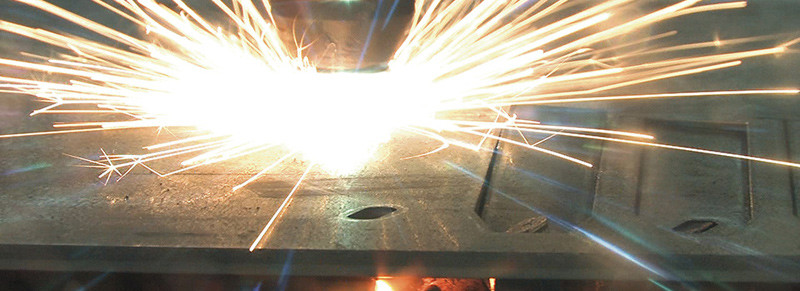

The focused laser beam is used to vapourise the material to be cut, however, an additional cutting gas, or assist gas, is needed to blow or remove the molten material through the thickness of the metal being cut. It is exactly similar in principle to oxy / acetylene or oxy / propane cutting, where a fuel gas and oxygen are used to heat the metal until molten and then an additional nozzle blows oxygen through the material thickness to remove the molten metal. But although the principles are similar between oxy / acetylene and laser cutting, the control and fine detail obtainable from the laser process is far superior to most other heat cutting processes.

Laser Cutting and Welding advantages:

- Dies / tools not required

- Clean efficient small beam diameter

- Minimal cleaning after cutting

- Very small HAZ

- Contour head for uneven sheets

- Tube Ø250mm x 800mm long

- Keyhole welding

- Welding dissimilar metals

- Minimal post weld cleaning using laser methods

- Up to 4mm full depth weld (depending on material type)

- Special finish materials cut with protective coating intact

Factory Tour

You can check out our 5 axis Cell 3000 during a store Tour. To arrange this please contact Mike Martyn - DD - 01273 252 563.